Avoid breaking glass due to stress or shock

Avoid glass breakage due to stress or shock

Why choose to buy technical films from companies in the sector? For two simple reasons: the first because you can take advantage of a consultancy in the correct choice of materials with consequent customization in the cuts; the second reason is to avoid possible glass breakage (stress or shock) due to the installation of unsuitable materials. Let's see together why the windows can break when installing the films:

Energy reflected and absorbed by the glass and solar film system

Solar control films for windows reduce the amount of solar heat in a building by reflecting and absorbing incoming solar energy. The "absorption" part is the one that can increase the risk of breaking the glass. Absorption heats the glass which creates a greater extension than without the film. This delay, combined with a "defect" condition, increases the risk of breakage. Glass is not a perfect material, it is in fact defined as an amorphous solid (devoid of long-range order in the position of atoms). Defects are therefore both inherent in the glass and introduced by an imperfect finish or installation (absent or poor grindings, screws in contact with the glass ...). Tempered glasses are the only glasses that can withstand high thermal stresses (even 200 ° C of thermal variation), for this reason, for example, on the side and rear windows of cars we can mount pure blackout films (very high thermal absorption), which which we cannot normally do at home since our glasses are almost never tempered.

External Shading

External shading is the first cause of glass breakage: the sun hits part of the window, causing it to heat and expand, while the shaded part does not change temperature and remains cooler. The consequent stress of the two parts (a hot part expanding and a part not) causes the glass to break along the demarcation line of the shadow. Films with high thermal absorption (over 40% -50%) accentuate this phenomenon even more; for this reason the laying of films (especially internal ones) with a high absorption index must always be subject to evaluation. This problem never arises when installing reflective outdoor films (from 70% to higher).

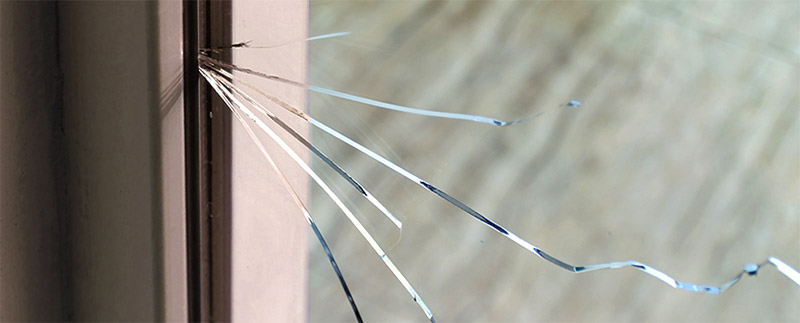

Chipped edges and grinding

Some common causes of glass breakage cannot be detected before installing the film. The edge of the glass is hidden inside the window frame where a chip or crack can cause it to break. The glass sheets must be ground before installation in a window. This grinding provides a smooth, rounded surface which greatly increases the strength of the glass edge. It may happen, in the production of low-cost windows, that an incorrectly treated glass is used. Any chipping or scratching of the edge greatly reduces the overall strength of the glass plate. Cracks often originate from these points when the glass undergoes heating and cooling cycles (expansion and contraction).

Stress at the edges

Another major cause of glass breakage comes from stress on the edge of the frame. The glass should be installed with a small "expansion" space on all sides. If the glass is a little too big and mounted leaning against the frame without spaces, or against a mounting screw, it happens that the stress due to overheating due to solar radiation becomes excessive and can introduce breaking points. If the glass breaks due to solar thermal stress, the crack usually begins at one of these stress points.